Design Optimization of Compact Superalloy Heat Exchangers for Extreme Temperature and Pressure Conditions

Post date: October 4, 2020

Postdoc: Dr. Kaiyuan Jin

Students: Akshay Bharadwaj Krishna, Zachary Wong

Faculty: Timothy S. Fisher

Sponsor: Advanced Research Projects Agency-Energy (ARPA-E), US Department of Energy

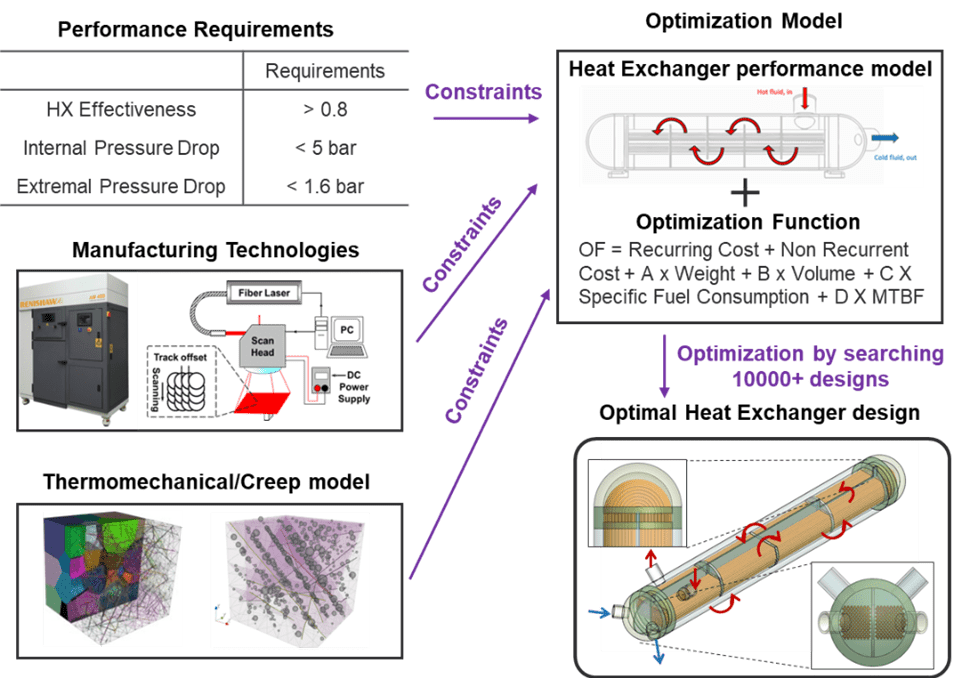

Summary: Heat exchangers are critical components of a variety of energy systems for providing efficient thermal energy exchange and significant heat recovery. Manufactured with an advanced nickel-based alloy, ‘superalloy‘ heat exchangers can handle working fluids (e.g., sCO2) at extremely high temperatures and pressures. Operated at these conditions, thermal systems can achieve unprecedentedly high energy conversion efficiency, low system footprint, and low capital cost. Targeting high thermal performance, high thermomechanical stability, and low cost, these heat exchangers require simultaneously achieving large heat transfer area, pressure-resistant structures, and compact heat exchanger size, the combination of which is challenging for current designers and manufacturers.

Our research team is conducting a systematic investigation for the design optimization of compact superalloy heat exchangers in shell-and-tube configurations. The study focuses on understanding the heat transfer physics of convection flows over complex heat transfer geometries, predicting thermal and hydraulic performance, and optimizing multiple design parameters to produce a reliable, durable, manufacturable, and cost-effective heat exchanger design. Both experimental and CFD tools will be utilized to develop refined correlations of friction factor and Nusselt number. By incorporating the developed correlations, we are developing a numerical model that employs the concept of volume averaging to predict the thermal performance and an optimization routine to provide an optimal heat exchanger design. Our study demonstrates a complete process of testing, modeling, and optimizing a compact superalloy heat exchanger and will pave the way for developing new heat exchanger technologies for operation at extreme conditions.